Focus on high-temperature nanocomposites

High quality supplier of synthetic stone mold insulation board

Focus on high-temperature nanocomposites

High quality supplier of synthetic stone mold insulation boardGlass fiber board (FR4)

- Product parameters

-

Introduction:

Describe

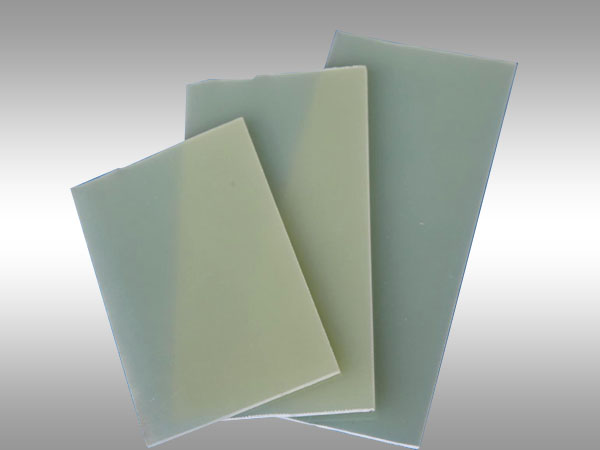

Epoxy board (FR-4)

Epoxy board (FR-4) features high mechanical and dielectric properties, good heat resistance and moisture resistance, and good machinability.

Use of epoxy board: used as insulating structural parts in motors and electrical equipment, including switches of various styles, electrical insulation, FPC reinforcement boards, carbon film printed circuit boards, computer drilling pads, mold fixtures, etc. (PCB test rack) and can be used in humid environment conditions and transformer oil, which is widely used.

Specification of epoxy board: 0.1-50 * 1.02M * 1.22M

main performance

Project unit: epoxy glass cloth laminate

Vertical impact strength ≥ Mpa 340

Parallel layer impact strength KJ/㎡ 33

Vertical layer electric strength ≥ (90+2 ℃ in oil) MV/m 14.2

Parallel layer impulse breakdown voltage ≥ (90+2 ℃ in oil) - KV 35

Relative dielectric constant ≤ - 5.5

Dielectric loss factor ≤ - 0.04

Insulation resistance after immersion ≥ Q 5 * 10

Water absorption 1mm ≤ Mg 18

Color - Natural

Nominal area of laminate: 1.02M * 1.22M

FR-4 Performance Characteristics

Vertical layer bending strength A: normal: E-1 / 150150 ± 5 ℃ ≥ 340Mpa

Parallel layer impact strength (simply supported beam method): ≥ 230KJ / m

Insulation resistance after immersion (D-24/23): ≥ 5.0 × 108Ω

Vertical layer electric strength (in 90 ± 2 ℃ transformer oil, plate thickness 1mm): ≥ 14.2MV/m

Parallel layer breakdown voltage (in transformer oil at 90 ± 2 ℃): ≥ 40KV

Relative dielectric constant (50Hz): ≤ 5.5

Relative dielectric constant (1MHz): ≤ 5.5

Dielectric loss factor (50Hz): ≤ 0.04

Dielectric loss factor (1MHz): ≤ 0.04

Water absorption (D-24/23, plate thickness 1.6mm): ≤ 19mg

density:1.70-1.90g/cm&;sup3;

Combustibility: FV0

Color: natural color

Executive standard: GB / T1303.1-1998

FR-4 process performance:

(1) FR-4 melting point of pressing plate in manufacturing process (203 ℃)

(2) High chemical resistance

(3) Low loss coefficient (Df 0.0025)

(4) Stable and low dielectric constant (Dk 2.35)

(5) Thermoplastic materials

FR-4 Application

FR4 epoxy glass fiber board (epoxy board; The main specifications are 1000 * 2000 mm, 1020mm * 1220mm. Because of the advantages of raw materials, it ensures high-quality and cheap, timely delivery, has a stable customer base at home and abroad, and enjoys a high reputation.

FR-4 copper clad plate

FR-4 yellow material and white material, FR-4 epoxy glass cloth laminate, according to different uses, are generally called FR-4 Epoxy Glass Cloth, insulating board, epoxy board, epoxy resin board, brominated epoxy resin board, FR-4, glass fiber board, glass fiber board, FR-4 reinforcement board, FPC reinforcement board, flexible circuit board reinforcement board, FR-4 epoxy resin board, flame retardant insulation board, FR-4 laminate, epoxy board, FR-4 optical board, FR4 glass fiber board, epoxy glass cloth board, Epoxy glass cloth laminate, PCB drilling pad. Main technical features and applications: stable electrical insulation performance, good flatness, smooth surface, no pits, thickness tolerance standard, suitable for products with high performance electronic insulation requirements, such as FPC reinforcement board, PCB drilling pad, glass fiber meson, potentiometer carbon film printed glass fiber board, precision planetary gear (wafer grinding), precision test plate, electrical (electrical) equipment insulation brace partition, insulation pad, Transformer insulation board, motor insulation parts, grinding gear, electronic switch insulation board, etc.

Dongguan Xulian Electronic Technology Co., Ltd

Telephone:0769-87980772 Fax:0769-87988687 Filing No:

Keywords: synthetic stone, wave soldering fixture, reflow soldering fixture, mold insulation plate, plastic mold, fixture, electronic materials, high temperature resistant materials, engineering materials